| AT89LP2052

/ AT89LP4052 industrial controller Board

|

Hardware

An 8 bit 8051 compatible Atmel LP microcontroller controls the

basic components (e.g. inputs / outputs / I²C) on this board and allows the

serial communication with the Host System. This board is part of a Quality

Process control unit in the liquid food industry (automatic measurement of

several important Values like O2, CO2, pressure , alcohol, extract...

in gas and liquid in bottles in one single step). This board,

and some additional Software, replaced an existing Design with Simatic S7.

The board supports the following interfaces:

- I2C (2 wires)

- SPI (Serial Port Interface, 4 wires)

- RS232 (TxD, RxD) or

- ISP (in System Programming) via ISP Cable or serial Port

There is no additional external RAM on the board

because data storage can be achieved by Host software. The System configuration

(and information for product service) can be stored in an EEPROM (1kbit to 16

kbit).

This AT89LP2052 / AT89LP4052 industrial control board has several

features:

- serial Port with Maxim 232 or FTDI USB chip

- 2 8bit Output Ports with ULN Drivers (e.g. for Step motors or valve control)

- one 8 bit I/O Port (PCF device)

- 2 Pinheads for Port 1 and Port 3, Reset connector

- Start / STop connector

- two 24V relays

- I2C connector (e.g.for external ADC Board)

- ISP programmable via serial port with SS Signal support

- Atmel compatible AT89ISP Pinheader

- Easy IDE: upload your program (hex file) via ser. Port and start the

device

- On Board EEPROM

You can find more details about the microcontroller in the Atmel

specifications: (

Atmel specs ).

|

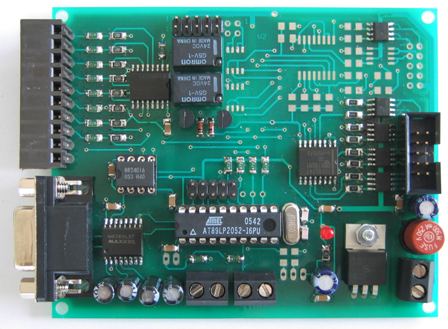

A picture of our prototype:

The EEProm is removable. This allows

different system configurations in the field without any flash programming.

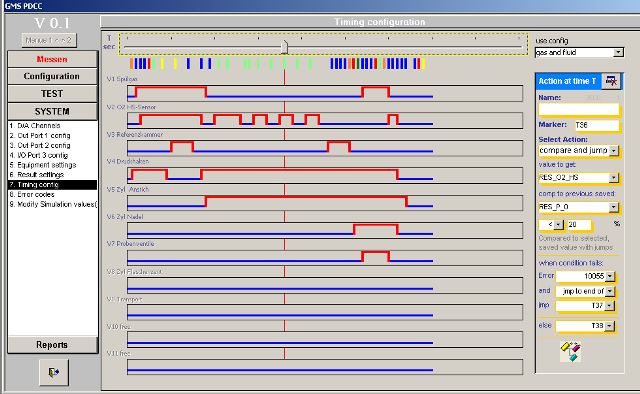

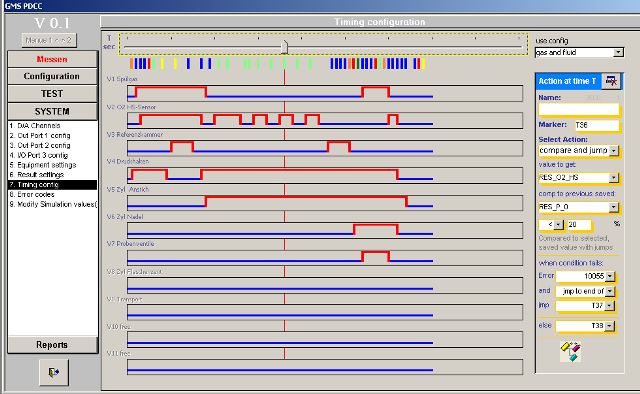

The GMS hostsoftware supports the timings for the I/O Ports and

can do actions at every timerintervall (e.g. measurements, wait for

input, compare and jump...).

|

Software

GMS offers specific host and

microcontroller software for interested customers. The following image is

an example for a timing configuration for the Output Ports driving 12 Volt

valves. At every cycle time the software can

digitize different 4-20mA analog input channels or communicate

with different measurement equipment to control the complete Process. All

results ar stored in a Microsoft database.

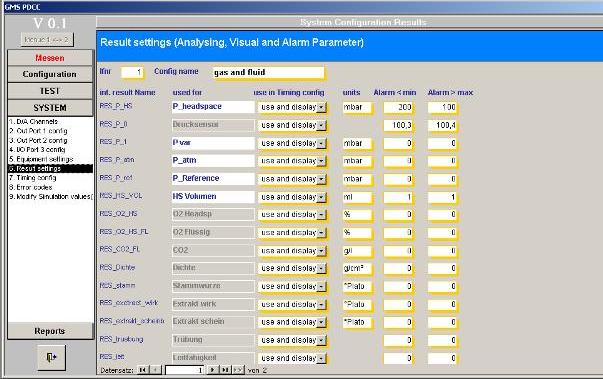

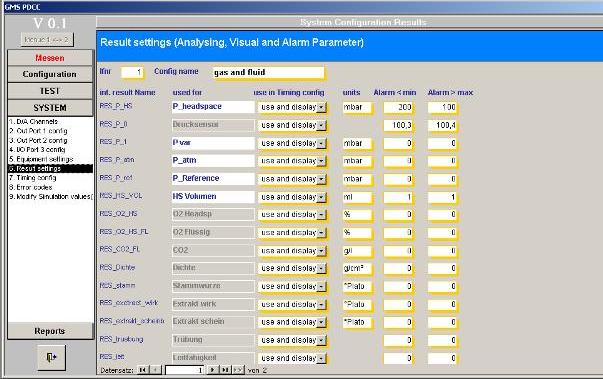

This is an example for an user interface to

configure and customize results from different equipments (e.g. equipment

internal DA converter or external equipments like O2 / CO2 Analyzer or

pressure sensors)

Any input or questions are

welcome: Mail

j.hulzebosch@gms2000.de